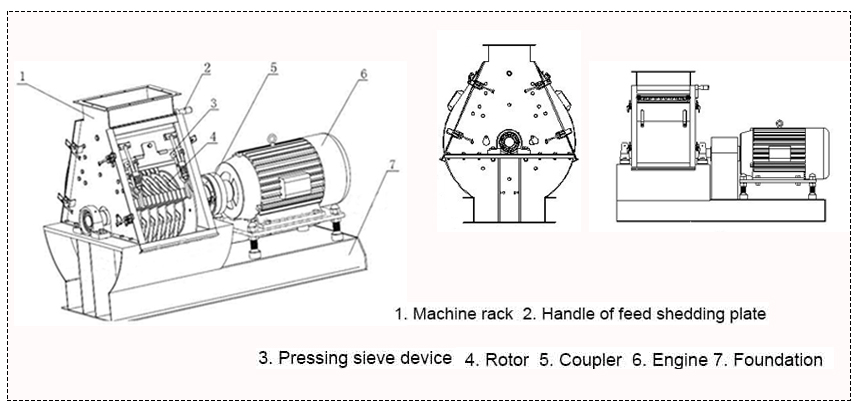

Water drop type hammer mill

Feed hammer mill also called feed grinding machine can be divided into wide chamber feed hammer mill, A-series feed hammer mill and waterdrop feed hammer mill, which available,mostly used for fine grinding and widely used in animal feed pellet plant or aquatic and poultry feed production. install in the animal feed pellet production line. Feed hammer mill is a necessary equipment in animal feed pellet plant. We supply three types of feed hammer mills, this one is called common feed hammer mill mainly used for grinding grain products that are to be made into livestock feed pellets or poultry feed pellets.

Application

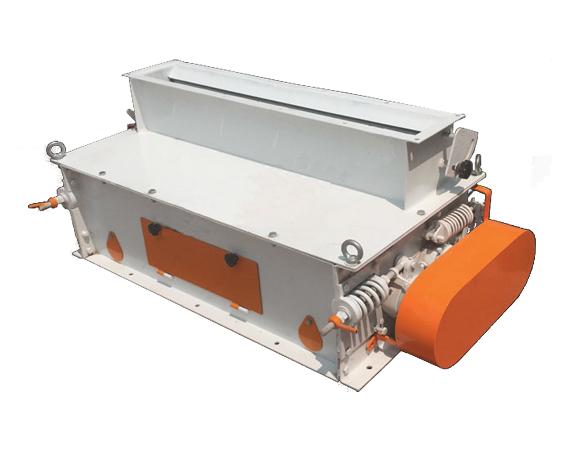

1.The aquatic feed hammer mill is widely adopted in large and medium scale aquatic or poultry feed pellet manufacturing industries. It’s a pretreatment equipment to cut down the size of the feed raw materials with a water content of 8%-13% for further processing. As a fine grinding machine, its grinding fineness can reach 50 mesh. The common raw materials for the aquatic feed hammer mill are grains such as wheat, maize, rice, soybean, groundnut, millet or other solid materials such as bone, dry meat and so on.

2.The poultry feed hammer mill is mainly used in large and medium scale animal feed manufacturing industries and food processing enterprise. It can be used for both general grinding and fine grinding. Equipped with the removable sieve tooth plates, the poultry feed hammer mill is available for different fineness requirements of the feed material.

Raw Material

It is the the ideal crushing equipment of animal feed, poultry feed, animal food, chemical pharmaceutical, corn, sorghum, wheat, soybeans, peanuts, grain, legumes , particle feed, rice husk ,straw.

Features and advantages

1) Adopting international advanced technique, crush room is designed as water drop figure. With special twice crush design, the output can be increased by 25%.With adjustable hammer screen space and optimized arrange of hammer pieces, it can fully to meet the coarse and fire crushing requirements.

2) With full open operating door, screen is tensioned outside and can be maintained and replaced easily.

3) Safe and environmental, inset seal avoids the dust from overflowing and improve the work conditions.

4) Tested by the high precision balancing machine, the hammer mill won’t move a bit when it run, which reduces noise and prolongs motor bearing’s life.

5) Feeding with speed governing feeder, feeder with belt transport or self-scavenging impeller feeder.

‚ÜëDoes not include impeller feeder

Parameter

| Model | Capacity (T/H) | Power (KW) |

| SFSP56*36 | 1 - 5 | 22 |

| SFSP56*40 | 2 - 8 | 39 |

| SFSP60*60 | 4 - 12 | 55 / 75 |

| SFSP66*80 | 15 - 25 | 90 / 110 |

| SFSP66*100 | 20 - 30 | 132 / 160 |

Purpose of crushing raw materials

1. Increase the specific surface area of the feed and increase the utilization rate of the animal.

a. increase the contact area of digestive enzymes to raw materials

b.Reduce the chewing energy consumption of the animal feeding process, which is conducive to improving feed compensation.

C, the crushed raw materials are easy to mature in the granulation and tempering stage.

2. Improve the quality of subsequent processes and improve work efficiency.

a. The material size is the same or similar, the mixing uniformity is higher.

b. The pulverized feed can greatly reduce the power consumption in the granulation process.

Reply comment