Dry Floating Fish Feed Machine

Dry floating fish feed machine is dry type small floating fish feed machine used for making feeds of different pets, such as rabbits, shrimps, dogs, cats, donkeys, and foxes.

Application

The floating fish feed machine uses corn, soybean (bean cake), fish power and other raw materials, and can be directly added into the machine to expand and produce different particle shapes, unique taste, rich nutrition and fine tissue, suitable for dogs, cats, fish and birds. Feeds of different pets, such as rabbits, shrimps, dogs, cats, donkeys, and foxes. Suitable for professional farmers, small and medium-sized feed mills and research institutions.

Classification Features of Fish Feed Extruder

The Fish Feed Pellet Extruder can be divided into two types: Dry type fish feed extruder and Wet type fish feed extruder. The differences and features of the dry type and wet type pellet feed extruder:

1. Dry type fish feed extruder does not need the steam boiler while the wet type is with the conditioner and need to equip the steam boiler. So the dry type fish feed pellet extruder machine is cheaper and easier to use and operate

2.The feed pellet made by wet type fish feed pellet machine is more smooth and with better quality because the material is ripen and mixed enough in the conditioner compared with the dry type extruder.

3.The capacity of the wet type is higher than the dry type feed pellet extruder machine, so usually the wet type fish feed extruder machine is suitable for large feed pellet factory while the dry type fish feed pellet machine is better and economic for the small and medium size user or factory.

Dry Floating fish feed machine technical parameters

| Name | Capacity (T/h) | Host power (Kw) | Feeding power (kw) | spiral diameter (mm) | Cutting power (kw) |

| DGP40-C | 0.03-0.04 T/H | 5.5 KW | 0.4 KW | Φ40 | 0.4 KW |

| DGP50-C | 0.06-0.08 T/H | 11 KW | 0.4 KW | Φ50 | 0.4 KW |

| DGP60-C | 0.1-0.15 T/H | 15 KW | 0.4 KW | Φ60 | 0.4 KW |

| DGP70-B | 0.18-0.2 T/H | 18.5 KW | 0.4 KW | Φ70 | 0.4 KW |

| DGP80-B | 0.2-0.3 T/H | 22 KW | 0.4 KW | Φ80 | 0.6 KW |

| DGP90-B | 0.3-0.4 T/H | 37 KW | 0.6 KW | Φ90 | 0.8 KW |

| DGP120-B | 0.5-0.6 T/H | 55 KW | 1.1 KW | Φ120 | 2.2 KW |

| DGP135-B | 0.7-0.8 T/H | 75 KW | 1.1 KW | Φ133 | 2.2 KW |

| DGP160-B | 1-1.2 T/H | 90 KW | 1.5 KW | Φ155 | 3 KW |

| DGP200-B | 1.8-2 T/H | 132 KW | 1.5 KW | Φ195 | 3.0-4.0 KW |

Difference between Dry Type and Wet Type Extruder

1.Dry type fish feed extruder does not need the steam boiler, so the dry type fish feed pellet extruder is cheaper and easier to use and operate.

2.The feed pellet made by wet type fish feed extruder machine is more smooth and with better quality because the material is ripen and mixed enough in the conditioner compared with the dry type extruder.

3.The capacity of the dry type feed extruder machine is lower than the wet type fish feed extruder machine, so usually the dry type fish feed extruder machine is better and economic for the small and medium size user or factory.

Advantages

1. The extruded pellet feed can be floated on water over 12 hours, no need worry about the pollution.

2. The raw material had been effectively killed harmful bacteria by high temperature and high pressure, to ensure the feed hygiene

3. Different moulds can be chosen to make pellets with different diameters and shapes.

4. This aquatic products pellet feed processor is provided with solitary switch board, and assurance operating personnel's that can be fine life safety still is provided with the cutting blade that can adjust from top to bottom, can adjust fodder granule size as required.

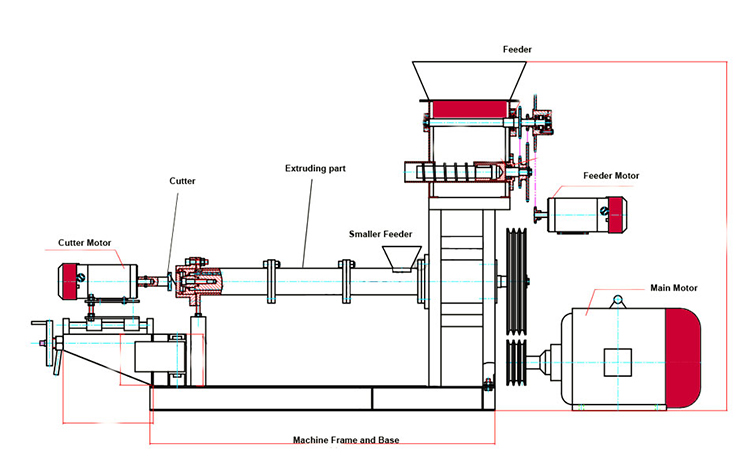

Fish feed machine working principle

Before using the aquaculture feed pellets maker, needs to be the entire aquaculture feed pellets forming machine structure simple to understand, we first material poured into the stirring compartment, water and adding suitable, and then start the feeding motor and main motor, rotating the driving wheel to drive it, so as to drive the driven wheel is rotated, thereby bringing feeding blade rotated, so that the raw material is stirred well, then mix well, the stirring in the stirred material is poured into the extruder system, due to the effect of the protective cover, and then start the cutting electric motor, thereby driving the rolling roller is rotated, thus achieving the object of the extruded material so that the particles produced from the extruded hole, squeezed It is cut out of the material under the effect of rotation of the blade of a small particle, and finally slipping out of the machine from the discharge port.

Reply comment