1T/H -1.2T/H Floating Fish Feed Plant

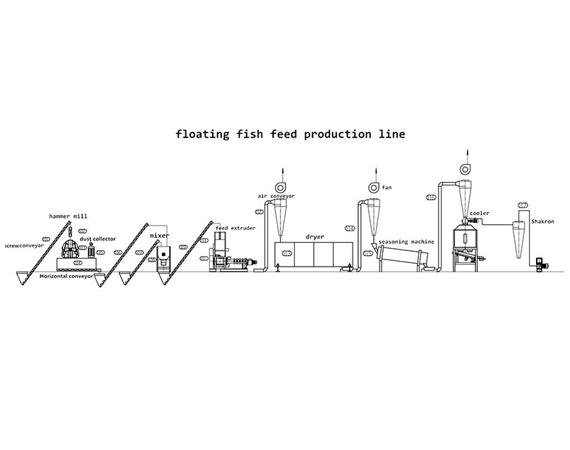

Main Machine: water-drop hammer mill, mixer, feed extruder, air conveyor, dryer, fan, seasoning machine, cooler, screw conveyor and package machine

Pellet sizes: 1.5mm, 1.8mm, 2mm, 2.5mm, 3mm, 4mm, 5mm, 6mm, 6.5mm, 7mm

Application: extruding fish/dog/cat food pellets, suitable medium fish farms and pet/fish food industries

Capacity: 1.5t/h-2t/h

Main Materials: most of machine is made of carbon steel, main part is made of stainless steel

Product Introduce

As a feed machine manufacturer, own experts and R & D personnel for feed equipment, mainly produce dry and wet type fish feed extruder, small mesh-belt dryer, horizontal single-shaft mixer, and some feed and agricultural equipment. Especially, the main parts of feed extruder which plays important role of floating fish feed plant is screw, it is made of carbon steel or 304 stainless steel with high strength and long service life.

The cutter of fish feed extruder is important for feed pellets of yield and shapes, it is detachable and easy to maintanance.

Adopt PLC control system, detailed introduce how to operate the main machine.

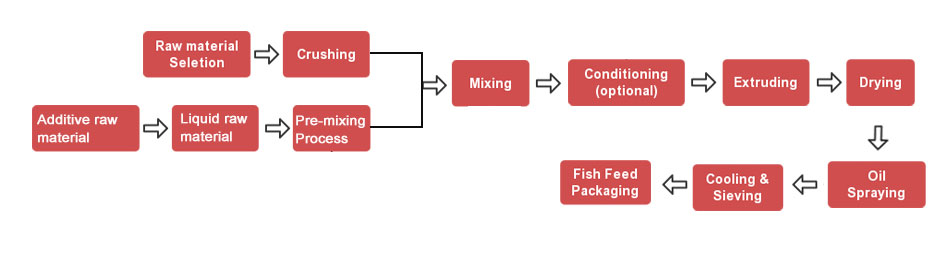

Fish Feed Manufacturing Process

1T/H Floating Fish Feed Plant Main equipment

screw conveyor â water-drop hammer mill â horizontal screw conveyor â 2 sets screw conveyor â horizontal single shaft mixer â screw conveyor â fish feed extruder â dryer â Pneumatic conveying system â seasoning machine â Pneumatic conveying system â cooler â Pneumatic conveying system â package machine

1T/H Floating Fish Feed Plant manufacturing process

Technical data

| No. | description | Notes | Qty. | Photos | |

| 1 | Spiral hoist | Power: 2.2kw Output: 1000-1500kg / h Dimensions: 4000 * 550 * 750mm Weight: 115kg | 1 |  | |

| 2 | Waiting for the crushing silo | Capacity: 2m3 Dimensions: 1500*1500*1800mm Weight: 220kg | 1 |  | |

| 3 | Pulse dust collector | Fan power: 1.5kw Output: 1000-1500kg / h Dimensions: 1550 * 900 * 1400mm Weight: 190kg | 1 |  | |

| 4 | grinder | Power: 22kw Output: 1000-1500kg / h Dimensions: 1600 * 960 * 1200 Weight: 680kg | 1 |  | |

| 5 | Horizontal screw conveyor | Power: 1.5kw Output: 1200-1500kg / h Dimensions: 2400 * 550 * 680mm Weight: 220kg | 1 |  | |

| 6 | Bucket elevator | Power: 3kw Output: 1000 * 1500kg / h Dimensions: 6500 * 650 * 500mm Weight: 420kg | 1 |  | |

| 7 | Spiral hoist | Power: 2.2kw Output: 800-1000kg / h Dimensions: 3200 * 550 * 750mm Weight: 90kg | 1 |  | |

| 8 | Waiting for the crushing silo | Capacity: 1m3 Dimensions: 1200 * 1200 * 1500mm Weight: 120kg | 1 |  | |

| 9 | Horizontal spiral band mixer | Power: 7.5kw Yield: 500kg / batch, each batch takes about 10-15 minutes Dimensions: 2400 * 1050 * 1700mm Weight: 580kg | 1 |  | |

| 10 | Bucket elevator | Power: 3kw Output: 1000 * 1500kg / h Dimensions: 6500 * 650 * 500mm Weight: 420kg | 1 |  | |

| 11 | Vertical Mixer | Power: 2.2kw Capacity: 1m3 Dimensions: 1200 * 820 * 2800mm Weight: 260kg | 1 |  | |

| 12 | DSP135-B Pellet extruder | Main motor power: 75kw Feeding motor power: 1.1kw Tempering motor power: 3.0kw Cutting motor power: 2.2kw Output: 1000-1200kg / h Dimensions: 3750 * 1980 * 1800mm Weight: 2800kg Required steam volume: 0.3t / h The conditioner is made of carbon steel. You can choose stainless steel, but the price is slightly higher | 1 |  | |

| 13 | Pneumatic conveying system | Fan power: 3kw Unloader power: 0.75kw Production: 1000-2000kg/h Dimensions: 2450*750*1900mm Weight: 180kg | 1 |  | |

| 14 | Dryer | Mesh belt motor power: 4.0kw Feeding motor power: 1.1kw Fan power: 2.2kw*2 Circulating fan power: 0.55kw*2 Output: 1000-1500kg/h Dimensions: 8200*1650*2800mm Weight: 4400kg Required steam volume: 0.8t/h | 1 |  | |

| 15 | Pneumatic conveying system | Fan power: 3.0kw Unloader power: 1.1kw Output: 1000-2000kg / h Dimensions: 2200 * 750 * 2700mm Weight: 220kg | 1 |  | |

| 16 | Silo for waiting to be sprayed | Capacity: 2.5m3 Dimensions: 1700 * 1650 * 1800mm Weight: 240kg | 1 |  | |

| 17 | Drum sprayer | Host power: 2.2kw Oil pump power: 0.55kw Oil barrel heating power: 1.5kw Output: 1000-2000kg / h Dimensions: 5000 * 800 * 1550mm Weight: 380kg | 1 |  | |

| 18 | Pneumatic conveying system | Fan power: 3.0kw Unloader power: 1.1kw Output: 1000-2000kg / h Dimensions: 2200 * 750 * 2700mm Weight: 220kg | 1 |  | |

| 19 | Countercurrent cooler | Fan power: 4.0kw Shakeron unloader power: 0.75kw Discharge method is pneumatic discharge Output: 1000-2000kg / h Dimensions: 1800 * 1500 * 2400mm Weight: 980kg | 1 |  | |

| 20 | Pneumatic conveying system | Fan power: 3.0kw Unloader power: 1.1kw Output: 1000-2000kg / h Dimensions: 2200 * 750 * 2700mm Weight: 220kg | 1 |  | |

| 21 | Finished product silo | Capacity: 2.5m3 Dimensions: 1700*1650*1800mm Weight: 240kg | 1 |  | |

| 22 | Automatic quantitative packing scale | Power: 1.1 Production: â¤300 bags / hour Packing range: 20-50kg/bag Dimensions: 2400*800*2940mm Weight: 576kg | 1 |  | |

| 23 | Boiler | Boiler pressure: 0.4-0.8MPa Required steam volume: 0.8t / h Customers are advised to equip themselves | 1 |  | |

| 24 | Electrical control system | 1 | |||

| 25 | Air compressor | Power: 2.2kw | 1 |

Fish Feed Making Machine Application

Our fish pellet production line is perfect for the production of pellets from grains, grass, protein and molasses for commercial purposes. Our end product feed pellets have fine textures, are nutrient-rich, have a unique taste, and are of various shapes. They are perfect for aquatic animals like shrimps, gold-fish, cat-fish, tropical fish etc.

Extruded Fish Feed Pellets (floating & sinking feed)

If you own a breeding farm, and you have medium or big-size feed mills, our line of fish feed pellet machine is your best choice because they use super automation controls and are highly efficient. Please feel free to contact us if you have any questions about fish feed pellet making machine!

Reply comment