200 kg/h floating fish feed production line

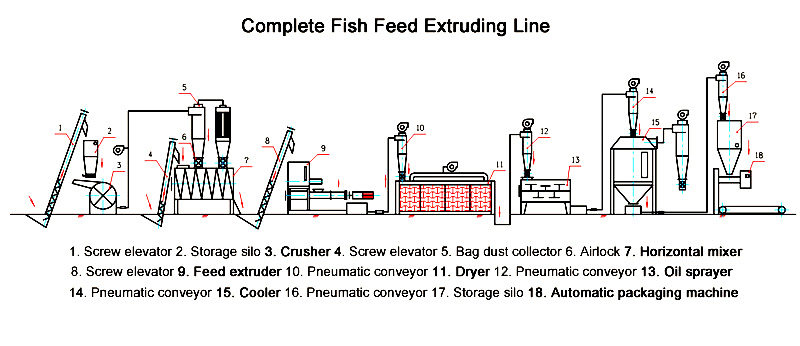

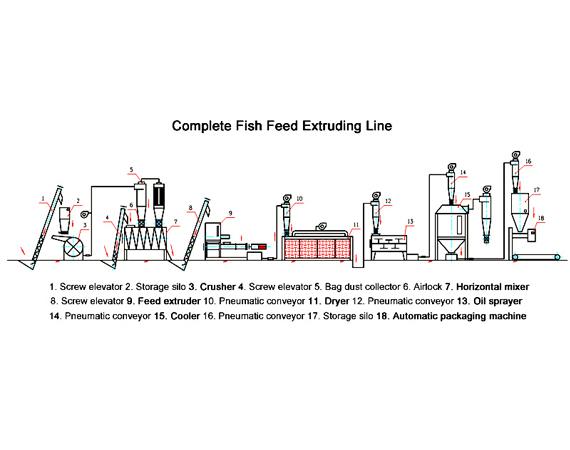

The manufacturing process of 200kg / h floating fish feed production line adopts secondary crushing and ingredients mixing, then completes the processing of aquatic expanded feed through expansion, drying, external spraying, cooling, crushing and screening. The fish feed plant produces soft pellets. Flat die and ring die feed pellet machine manufacturer hard pellet.

Application

Floating fish feed production line/plant is suitable for making commercial pellets from corn, maize, grass, grains, protein, molasses and so on, and final pellets with different shapes, unique flavor, rich nutrients and fine texture, are widely used as aquatic and pet feed like goldfish, tropical fish, catfish, shrimps, dog, cat and etc. Fish feed production line is the best choice for medium and big sized feed mills and breeding farms.

Floating fish feed production process includes the wet type feed processing with capacity of 1-20t/h and dry type feed processing with capacity of 100-800kg/h.

Grinder Mixer  Feeder Single Screw Feed Extruder  Conveyor  Multilayer Drying Equipment  Seasoning Line  Cooling  Conveyor  Packing Machine

Fish feed size range: 1.5mm, 2.0mm-10mm.

Features

1. International advanced & diced structure, adopt cutter positioning spring and cutting forms, frequency, cut out and dice various different lengths of particles.

2. Innovative, unique design, simple structure, easy disassembly is discharged transvestite, convenient operation.

3. Screw adopts special wear-resisting, high temperature resistant materials after the first conditioning heat molding, wear resistant and long life.

4. With distinctive turbocharged punching, ensure the quality and yield of feed.

5. Reasonable combination of practical spindle bearing, ensure the security and reliability of extrusion machine.

6. The main motor adopts high-quality Y series three-phase motor, ensure the power is strong.

7. Production buoyancy particles floating on the surface of extrusion feed can not keep 12 hours, fish and poultry bubble eat easy digest, artificial to observe the appetite of fish, won't cause feed waste water pollution.

Specification

180kg -200kg Floating fish feed production line technical data:

No. | description | Notes | Qty. | Photos |

| 1 | Grinder | Power: 7.5kw Capacity: 200-300kg / h Dimensions: 1350 * 930 * 1250mm Weight: 220kg | 1 |  |

| 2 | Vertical mixer | Power: 7.5kw Output: 50kg/batch, time required 5-6 minutes Dimensions: 1200*620*960mm Weight: 240kg | 1 |  |

| 3 | DGP70-B Puffed pellet machine | Main motor power: 18.5kw Feeding power: 0.4kw Cutting power: 0.4kw Output: 180-200kg / h Dimensions: 1650 * 1400 * 1350mm Weight: 600kg | 1 |  |

| 4 | Vertical dryer | Heating power: 5.2kw Fan power: 0.18kw Suction power: 1.1kw Output: 75kg/batch, time required 30-40 minutes Dimensions: 850*700*1600mm Weight: 115kg (Including automatic suction machine and hot air circulation device) | 1 |  |

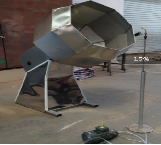

| 5 | Octagonal spray seasoning machine | Host power: 0.75kw Pump power: 0.37kw Output: 25kg/batch, the required time is 4-5 minutes Dimensions: 1200*1200*1500mm Weight: 95kg (Including oil pump and spray head) | 1 |  |

| 6 | Platform scale | Weighing interval: 0-300kg Table size: 40x50cm High-definition large screen, clear keys, stainless steel instrument head, 90-degree folding, ultra-high-precision sensor, adjustable scale angle for easy movement. | 1 |  |

| 7 | Electric sealing machine | GK9-370 Power: 200 watts Dimensions: 250*240*80mm | 1 |  |

Fish feed plant working principle

1. Crushing

Crushing coarse powder, such as maize, soy, oats, grass, etc.

2. Mixing

The raw materials such as corn meal, rice meal, soybean meal, fish meal, meat meal, grain meal, additives, etc. are added with a certain proportion of water to mix well and evenly.

3. Pelleting or extrusion

Extrusion is the process of feeding raw material through screw that causes kneading, grinding, mixing, inner shear force. This time heat has been occurred and cell wall will break away. The factor of heat, moisture, high pressure, time make material cooked. Starch will change status to gelatin called ÔÇ£GelatinizationÔÇØ. Mean time the structure of starch, protein, fat will be changed call ÔÇ£PlasticizationÔÇØ. This can form many shapes as require.

4. Conveyor

The feed particles produced are conveyed to the multi-layer drying equipment.

5. Multi-layer oven

oven is divided into electric oven, fuel oven, gas oven and steam oven. The temperature is adjusted by the control cabinet between 0 and 150 degrees. The inner of oven is stainless steel mesh belt, which conveys smoothly and has low failure rate. Feed pellets are circulated through multi-layer S-track, and dried to safe moisture content to increase shelf life.

6. Spraying seasoning line

spraying oil and food attractants on the oil sprayer. There are octagonal cylinder, cylinder, lifting single cylinder and double cylinder seasoning line. Oil and fat are sprayed on the feed surface according to the output and product properties. Meanwhile, meat powder and spices are sprayed evenly. After this process, the burrs and edges on the surface of feed particles can also be removed to make the surface of feed particles smoother.

7. Cooling conveyor

reduce the surface temperature of dried feed particles, promote oil solidification, reduce particle temperature, easy to package.

8. Packing machine

Manual sealing machine and automatic packing machine can be used.

Reply comment