1-2T/H Animal pellet feed line

1-2T/H Animal pellet feed line is large poultry feed manufacturing process plant, making pellets for a various variety of animals like fish, sheep, cattle, poultry, rabbit, chicken, duck, geese, etc. And the poultry feed plant is suitable for various poultry farms, feed factory and other animal farms.

Description

Animal pellet feed line can do most poultry and live stock mash and pellet feed. Through changing the grinder screen and ring die to produce more kinds of feed. Farm self use or commercial is a better stat investment.

Raw Materials for Feed Pelletizing

The feed pellets are usually made of corn, brown rice, paddy, sorghum and soybean meal etc.

Advantages of Feed Pellets

ŌśģDecreased ingredient segregation

ŌśģDecreased feed wastage

ŌśģEasy storage and transportation

ŌśģImproved palatability

ŌśģReduced selective feeding

ŌśģDestruction of pathogenic organisms

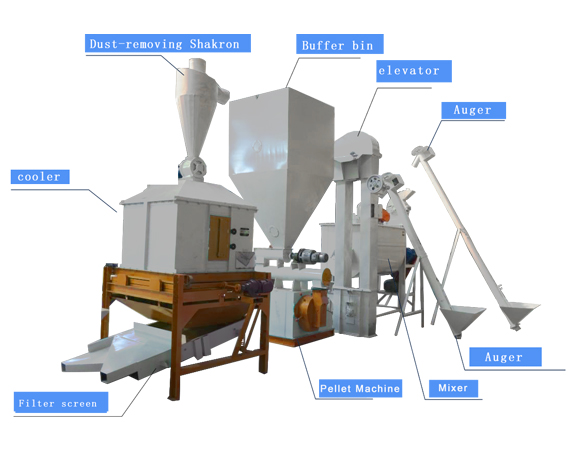

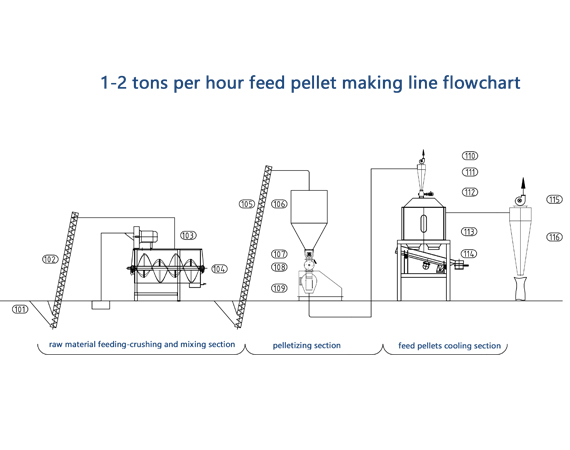

Manufacturing Processing

Crusher- This feed line start with two screw conveyors, one is for pellet material, transfer the pellet materials to grinder, after grinding pellet materials will be fine.The other one feed the mash materials to mixer directly.

Mixer- All the materials get together according to the formula in mixer. After mixing, all materials transfer to pelleting bin to ready pellet by one screw conveyor.

Feed pellet machine- When do pellet, feeder transfer mash feed to conditioner, inner conditioner can add high temperature steam to make the feed materialsŌĆÖ starch granulate, and kill a part of germs to reduce the cost of anti-epidemic. Starch granulate can improve digestibility of animal feeds. Then go down to pellet mill. Mash feed material get into the press area, rollers push the mash into the ring die hole, out be pellet. Pellet feed has many advantages, such as avoid animals being picky, convenient to transportation.

Cooling machine- Just pellet with high temperature and moisture,need cooling down and remove a part of moisture. Use a fan, cyclone and pipes to wind pellet to cooler. This cooling is against wind cooler. Exhaust fan let the wind pass from bottom of cooler, get in to cooler inner side, pass from pellet, take away the high temperature and moisture, till the temperature and moisture close to room temperature ┬▒5Ōäā, suitable for bagging.

Crumbler- Then discharge to crumbler, crumbler will make the big pellet be smaller to suitable for chick.

Screening machine- If no need be smaller will be down to bucket elevator to hoist up to rotary sifter, sifter will separate the fine from the pellet, then we get the product, go to finish product bin.

Packing Machine- At the end is the bagging process.

Design

Reply comment