200 Kg/Hr - 500 Kg/Hr Fish Feed Machine Line

Main Machine: screw elevator, crusher, single shaft horizontal mixer, fish feed extruder machine,dryer, seasoning machine, cooler and packing machine

Pellet sizes: 1.5mm, 1.8mm, 2mm, 2.5mm, 3mm, 4mm, 5mm...... 12mm

Application: extruding fish/dog/cat food pellets, suitable aquaculture farm and pet/fish food industries

Capacity: 200kg/hr-500kg/hr

Main Materials: most of machine is made of carbon steel, main part is made of stainless steel

Product Introduce

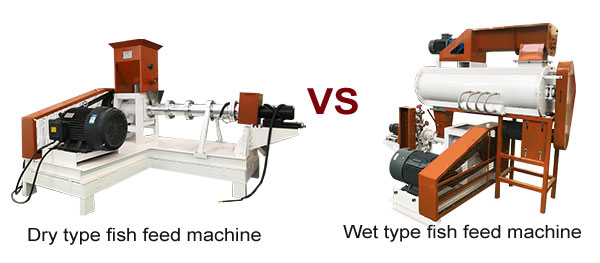

200 Kg/Hr - 500 Kg/Hr Fish Feed Machine Line produces floating, semi-floating and sinking feeds in accordance with feed formula, the feed line also can choose different, this is our popular feed production line selling all over the world. And the main machine is feed extruder machine that it has wet type fish feed machine and dry type feed machine.

Extrusion: a relevant response for the production of feed in aquaculture

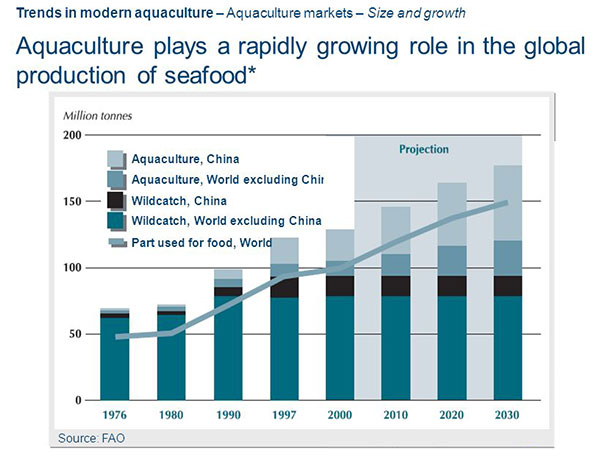

Aquaculture is the fastest growing animal feed sector in the world with an annual production of 34 million tonnes. A quarter of the fish consumed by humans is produced by aquaculture. With an estimated population growth of 25%, it will be necessary to produce between 41 and 69 million tonnes of fish per year until 2020.

Characteristic

Feeds intended for aquaculture should have high levels of digestible energy and amino acids available for growth and should be administered in the form of granules or extrudates. To allow the continuity and profitability of this activity, fish meal and fish oil will have to be used much less intensively in the future.

Advantages

Ability to extrude quality fish feed pellets.

Wide application. This feed pellets production line can be adopted in the production of various kinds of animal feed, such as dog, pig, rabbit, bird, cat, etc.

Advanced technology, high capacity and low energy consumption.

Shape and size of the final pellets can be adjusted by changing mold according to customer requirement.

Less floor space and needs low investment in construction work. The modular structure is convenient for assembly and disassembly, facilitating the shipment and installation.

PLC controlled, alarm device is available. The operation is simple and convenient.

Technical data

| No. | Description | Specification | Power (KW) | Capacity (KG/H) | Photo |

| 1 | screw conveyor | dimension:3500*820*630mm weight:106kg | 2.2 | 600-800 |  |

| 2 | silo | volume:1.5m3 dimension:1200*1200*1600mm weight:120kg |  | ||

| 3 | crusher | dimension:1600*1050*1300mm, weight:320kg | 15 | 500-700 |  |

| 4 | screw conveyor | dimension:3200*820*630mm, weight:95kg | 2.2 | 600-800 |  |

| 5 | cyclone and dust collector | dimension:1200*700*1800mm, weight:210kg | 0.75 | 600-800 |  |

| 6 | discharge | 0.75 | |||

| 7 | mixer | 15 minutes per bach dimension:1650*1050*1450mm, weight:350kg | 4 | 200kg/batch |  |

| 8 | screw conveyor | dimension:3500*820*630mm weight:106kg | 2.2 | 600-800 |  |

| 9 | GP120B-fish feed pellet machine | dimension:2400*1950*1600mm, weight:1700kg | 55+1.1+1.5 | 500-600 |  |

| 10 | pneumatic device | dimension:1850*850*650mm, weight:170kg | 2.2+0.75 | 600-700 |  |

| 11 | rotary dryer | dimension:4500*1500*2400mm, weight:1100kg | 27+0.75+3.0 | 500-600 |  |

| 12 | pneumatic device | dimension:1850*850*650mm, weight:170kg | 2.2+0.75 | 600-700 |  |

| 13 | Oil seasoning cylinder | 5000*850*1600mm , weight 320kg | 0.75+0.09+0.37 |  | |

| 14 | pneumatic device | dimension:1850*850*650mm, weight:170kg | 2.2+0.75 | 600-700 |  |

| 15 | cooling machine | cyclone:1850*850*650mm, weight:170kg cooler:2300*1300*1200mm weight:960kg | 4 | 600-700 |  |

| 16 | pneumatic device | dimension:1850*850*650mm, weight:170kg | 2.2+0.75 | 600-700 |  |

| 17 | finished product hopper | dimension:1600*1500*1800mm, weight:120kg | 2m3 |  | |

| 18 | packing machine | effective:â¤300bag/h packing:1-50kg/bag weight:586kg | 1.1 |  | |

| 19 | electric control |

Reply comment