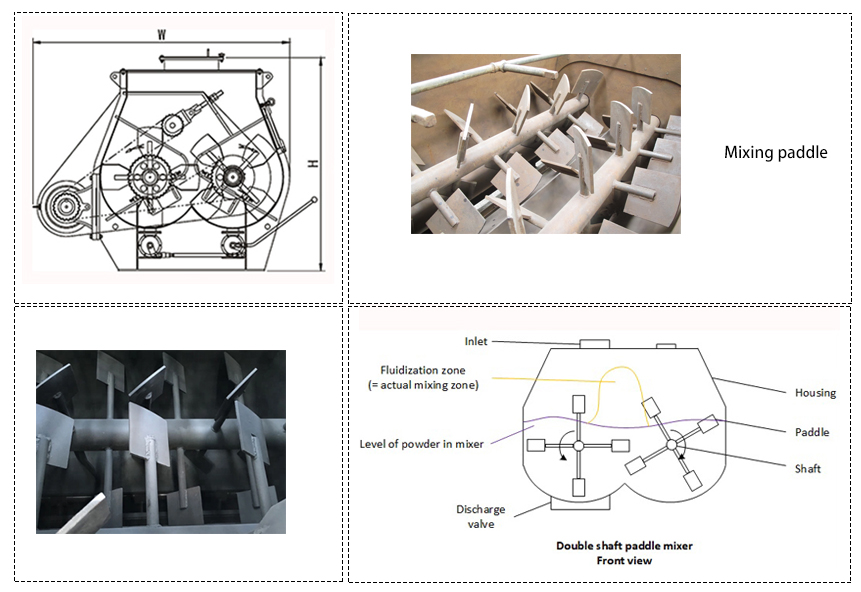

Double shaft paddle mixer

The double shaft mixer can mix corn flour cereal powder, soy flour, small fish bone powder, and so on. The double shaft horizontal mixer allows the material to be thoroughly mixed, which improves mixing uniformity.

Application

Double shaft paddle feed mixer machine Suitable for mixing of powder, flakes, pellets and other materials in premixing, poultry, aquatic feed, additive, chemical and cement industries.double shaft paddle mixer is a mixing device that mixes by the rotary stirring of the blades.

Advantages

1. The double shaft paddle feed mixer has a short mixing cycle and high mixing uniformity, which reduces the mixing time and greatly improves the production efficiency.

2. The variable loading range is large, suitable for different specific gravity, particle size and other materials in various industries: mixing of materials

3. Mixing does not produce segregation: after the machine is evenly mixed in 1 minute, the mixing of the mixed materials does not occur, and segregation does not occur due to large differences in specific gravity, particle size, etc., thereby obtaining a high-precision mixture;

4. Fast discharge and small residual amount: the full-length double-opening door structure is adopted at the bottom, so the discharge is quick and the residue is small.

5. Large amount of liquid added: adding 30% liquid can still mix the materials evenly, that is, can mix viscous materials.

Features

Mixing accuracy of 1:100.000/C.V. < 5%

Short mixing time of approximately 30-60 seconds

Versatile operation

Minimum filling degree will be 25% of the nominal capacity

Low power consumption

Relatively low height design

Available in different materials (S235JR/316L) and finishing standards (up to 0.3mÎź)

Parameter

| Model | Capacity (T/h) | Power (KW) |

| SLHY0.5 | 250 | 5.5 |

| SLHY1 | 500 | 7.5 |

| SLHY2 | 1000 | 15 |

| SLHY4 | 2000 | 30 |

Working principle

The double shaft paddle feed mixer consists of two horizontal shafts and a groove body, which are divided into two types: parallel flow and counter flow. When the flow is agitated, the two axes rotate in opposite directions, the blades rotate in the opposite direction, and the mud flows in the same direction. When the flow is reversed, the two axes rotate in the opposite direction, the blades rotate in the same direction, and the materials are returned. Prolong the mixing time of the material in the tank, which is conducive to uniform mixing. When dry mixing is carried out, the steering of the blade should be turned from the inner wall to the outer wall; when wet mixing, the blade should be turned inward from the outer wall to improve the pressing effect on the mud.

Reply comment