single shaft paddle mixer

The paddle mixer is divided into a twin-shaft paddle mixer and a single shaft paddle mixer. The single shaft paddle mixer in the feed processing machine can uniformly mix the raw materials. Single-axis paddle mixer for the mixing of powder, granules, flakes, blocks, hybrids and viscous materials in the feed, food, food, chemical, pharmaceutical, pesticide and other industries.

Application

SLHJ series horizontal single shaft paddle mixer is suitable for the mixing of powder, granule, flake, block and hetero-viscous materials in feed, food, chemical, pharmaceutical, pesticide and other industries. The single shaft paddle mixer in mixing equipment allows uniform distribution to ensure the quality of the mixed feed.

Performance characteristics

1. horizontal single shaft paddle mixer is a batch mixer with excellent mixing uniformity.

2. The gap between the rotor and the casing is small, so that the materials can be fully mixed, and the bottom is full-length to open the door, and the material residue is small.

3. The two ends of the body are tightly sealed to prevent the leakage of the two shaft ends.

4. The discharge door is pneumatically controlled, the action is more accurate and reliable, and the sealing performance is good.

5. The machine is equipped with a liquid adding device, and the distribution is evenly dispersed.

6. The overall structure is reasonable, the appearance is beautiful, and the operation and maintenance are convenient.

Features

Mixing accuracy of 1:100.000/C.V. <4%

Short mixing time of approx. 120 seconds

Discharge time of 15 seconds

Reliable sturdy construction

Low power consumption

Hygienic design

Easily replaceable and adjustable paddles

Parameter

| Model | Capacity (T/H) | Power (kw) |

| SLHD1 | 500 | 11 - 15 |

| SLHD2 | 1000 | 18.5 - 22 |

| SLHD4 | 2000 | 37 - 45 |

| SLHD6 | 3000 | 55 |

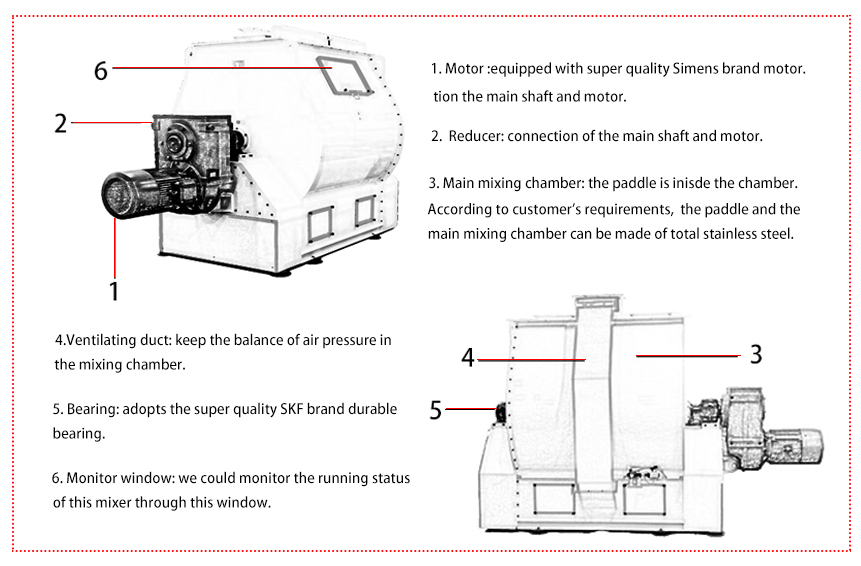

Structure and working principle

1.Rotor

The rotor consists of a shaft and a blade welded thereto. The angle between the blade on the shaft and the two sides of the blade ensure that the material is uniformly mixed in the mixer.

2. Body

The return air duct is installed on the air body to return the air to the discharge chamber when the material is being cut, so as to ensure the unloading of the material. There are inspection doors on both sides of the machine body, which makes maintenance and debugging more convenient.

3. Discharge gate

A sealing strip is arranged around the lower door frame of the lower part of the body. When the door is closed, the sealing strip on the discharging door body is close to the casing, so that the material in the machine does not leak out.

The discharge control mechanism is composed of a cylinder and a connecting rod. The discharge door is mounted on the shaft, and the cylinder reciprocates, and the link mechanism rotates the shaft, thereby driving the discharge door to open or close (the discharge door is closed when the cylinder piston rod is pushed out), and ensuring that the connecting rod is at the time of closing the door Dead point status.

4. Liquid addition

The liquid adding device is composed of a cover plate, a nozzle, and the like, and the liquid is sprayed through the nozzle in a fan shape, and a plurality of nozzles are evenly distributed throughout the entire length of the casing. The external tubing is connected by a hose to the internal thread of the cover.

Reply comment