Horizontal Feed Mixer

The horizontal feed mixer for feed is one of the important components in the feed granulation process. The horizontal mixer for feed allows the material to be thoroughly mixed, thus increasing the mixing uniformity.

Application

Horizontal feed mixers can be widely used in feed mills, farms, chemical plants, food plants, flour mills, etc. Suitable for premix, poultry feed, aquafeed, additives, chemical and pharmaceutical industries. The animal feed horizontal mixer can add different types of raw materials to the mixer in batches according to different animal formula requirements.

Features

â—ڈ Wide application: the ribbon mixer is widely used for feed, food additives, binder, silicone rubber, pigment, printing ink, paraffin, resin, vanishing cream, ointment, detergent, etc.

â—ڈ Large loading coefficient, small floor space, suitable for plant with large capacity and infrequent material changes.

Advantages

1. It has the characteristics of wide applicability, good uniformity of mixing, low residue of many materials and convenient maintenance, etc. It is an ideal equipment for mixing and processing of powdery materials.

2. The machine structure compact with good shape, covers an area of space less than other mixing equipment.

3. The machine also has the advantages of smooth operation, low noise, high loading coefficient and short mixing time

4. It is a new type of mixing equipment with high efficiency, high uniformity, high loading coefficient, low energy consumption, low pollution and low breakage.

Parameter

| Model | Power | voltage | Capacity | Mixing time(s) |

| SLHY0.3 | 1.5kw | 380V 50HZ | 150kg/batch | 180-240 |

| SLHY0.5 | 5.5kw | 380V 50HZ | 250kg/ batch | 180-240 |

| SLHY1.0 | 7.5kw | 380V 50HZ | 500kg/ batch | 180-240 |

| SLHY2.0 | 15kw | 380V 50HZ | 1000kg/ batch | 180-240 |

| SLHY2.5 | 18.5kw | 380V 50HZ | 1000kg/ batch | 180-240 |

| SLHY5 | 30kw | 380V 50HZ | 2000kg/ batch | 180-240 |

| SLHY7.5 | 45kw | 380V 50HZ | 3000kg/ batch | 180-240 |

Working principle

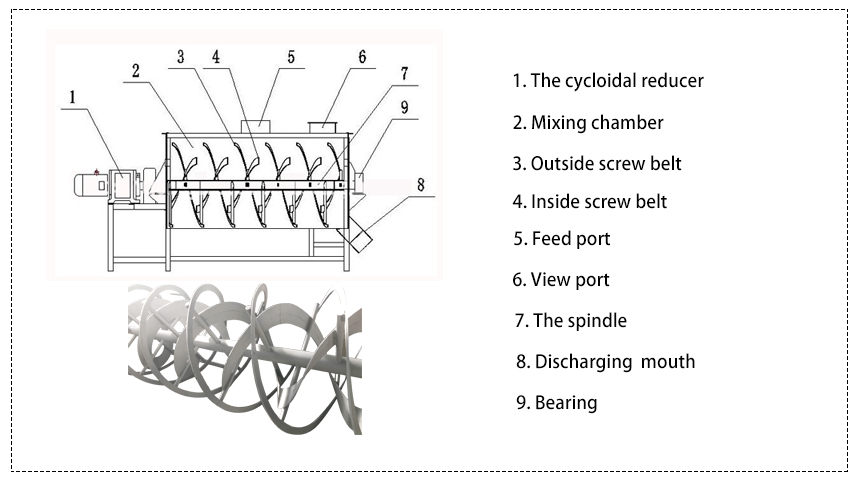

The speed reducer of the mixer drives the agitating shaft, the spiral ribbon on the shaft makes the materials turning up and down.The inner spiral pushes the material from middle to both ends, while the outer spiral presses the material from both ends to the middle, which helps discharging material, meanwhile lifting materials up along the inner wall of the mixer, forming a circulation of materials inside the machine to reach an even mixing effect.

Operation and Maintenance

1. After starting the mixer, check its running direction timely to avoid turning reversely.

2. The load of the mixer must not exceed the effective volume.

3. After using for 15 days for the first time, release the lubricant oil and clean the oil tank; change the lubricant oil in the speed reducer every three months, and fill grease to the bearing every two months.

4. Minor repair of the mixer is needed after 1800 hours’ normal running, mainly to check the lubrication point or replace the wearing parts; overhaul is needed after 4000 hours’ normal running, mainly to disassemble to check and clean all the components, replace or rectify all the wearing parts and standard parts.

Reply comment