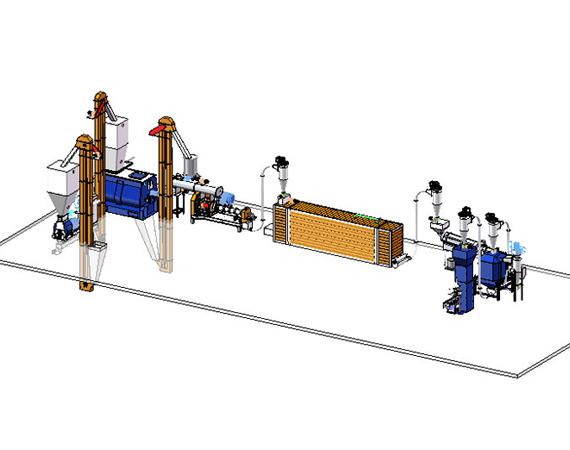

Dry type fish Feed Production Line

Floating fish feed production line with capacity of 100-500kg/h is designed for making commercial pellets from corn, maize, grass, grains, protein, molasses and so on, and final pellets with different shapes, unique flavor, rich nutrients and fine texture, are widely used as aquatic and pet feed like goldfish, tropical fish, catfish, shrimps, dog, cat and etc.. This feed production line adopts automation control, which is the best choice for medium and big sized feed mills and breeding farms. Our professional experts can design different capacities to meet customersÔÇÖ specific demands.

Product description

As a floating fish feed machine manufacturer, exporter and trade company, our market mainly includes South Africa, Philippines, India, Malaysia, Australia, Pakistan, Nigeria, Turkey, Chile, Maputo, Tanzania, Zimbabwe, America, Venezuela, Thailand, Myanmar, Vietnam, etc almost all over the world

Mainly provide dry type fish feed machine for making fish feed pellets for kinds of fishes. Floating fish feed making machine is used to make the pellet from the grain, the soybean, the cereal, or other materials.

Fish feed making machine installed in floating fish feed plant can make fish feed, shrimp feed, catfish feed, golden fish feed etc kinds of fishes and also pet foods.

Main fish feed machine technical data

| Dry fish feed machine | |||||

| Name | Capacity (T/H) | Host Power (KW) | Feeding Power (KW) | Spiral Diameter (MM) | Cutting Power (KW) |

| DGP40-C | 0.03 - 0.04 T/H | 5.5 | 0.4 | Φ40 | 0.4 |

| DGP50-C | 0.06 - 0.08 T/H | 11 | 0.4 | Φ50 | 0.4 |

| DGP60-C | 0.1 - 0.15 | 15 | 0.4 | Φ60 | 0.4 |

| DGP70-B | 0.18 - 0.2 | 18.5 | 0.4 | Φ70 | 0.4 |

| DGP80-B | 0.2 - 0.3 | 22 | 0.4 | Φ80 | 0.6 |

| DGP90-B | 0.3 - 0.4 | 37 | 0.6 | Φ90 | 0.8 |

| DGP120-B | 0.5 - 0.6 | 55 | 1.1 | Φ120 | 2.2 |

| DGP135-B | 0.7 - 0.8 | 75 | 1.1 | Φ133 | 2.2 |

| DGP160-B | 1 - 1.2 | 90 | 1.5 | Φ155 | 3 |

| DGP200-B | 1.8 - 2 | 132 | 1.5 | Φ195 | 3.0 - 4.0 |

Features of Feed Pellet Production Line

1. New technology, low energy consumption.

2. The modular structure is convenient for assembly and disassembly, facilitating the shipment and installation.

3. PLC controlled, alarm device is available. Easy to operate and maintenance.

4. Final pellet shapes and sizes can be various by changing the mould. For fish and shrimp feed pellet, the floating time in water can be adjusted by the extrusion degree adjustment.

5. Processing is processed at high temperature instantaneous process, greatly reducing the decomposition of nutrients in feed, at the same time improve the protein (through the degeneration of protein) and starch (through starch paste) digestibility, to improve the palatability of the product.

6.High temperature kills some bacteria, which can improve the nutrition of feed pellets and improve the immunity of fishes

7. In order to ensure the quality and the capacity, there is the special pressure-increased device. Besides, the electric heating device improve the feed expansion rate.

Details of floating fish feed production line

1. A wide range of raw materials such as corn, wheat bran, paddy, soybean meal, paddy rice, sorghum, etc. The raw materials is experienced by the high temperature and high pressure, which can kill the salmonellosis and bacterial infections.

2. Besides floating fish feed and sinking fish feed, this production line can also produce high quality feed for pet like dog, cat and etc., applicable for fish farm holders and pet feed manufacturers.

3. The diameter of the pellets can be from 1.5mm-15mm.

4. Capacity: 100-500kg/h. We can also customize different fish feed pellet plant depending on your raw materials and specific requirements.

How to Make Fish Feed Pellets?

A complete fish feed pellet production line generally includes the following process:

Material crushingÔÇö>material mixingÔÇö>extruding processÔÇö>pellets dryingÔÇö>oil spraying processÔÇö>pellets coolingÔÇö>pellet packing.

1.Raw material selection

Besides the nutritional value, the processing characteristics of aquatic feed raw materials should also be an important factor to be concerned about. The ideal processing characteristics of aquatic feed raw materials are not only manifested by larger output and less energy consumption in crushing, mixing or granulation, the more important point is that the final produced fish feed pellets must have good stability in water.

Starch is usually an important component in aquatic feeds, and the content of starch can be 5% to 60%. It is suggested that the starch content of sinking fish feed is 10% to 15%, and the starch content of floating fish feed is no less than 20%. In extruding fish feed pellets, carbohydrates act as adhesives, suspending agents, and emulsifiers. It is an important determinant of many structures and special sensory properties of extruded products.

2.Material Grinding

Various kinds of raw materials should be ground to the required size by feed hammer mill. Particle size of raw material has a direct effect on the pellets making efficiency. There are two types of feed hammer mill: fish feed hammer mill and fish feed crusher, which can meet your requirements for fish feed pellets making.

3.Material Mixing

Powdery feed materials need to be blended evenly to increase diet uniformity and improve the feed stuff quality. Featured by low energy consumption and high mixing accuracy, our feed mixer is widely used in feed pellets plant. Feed mixer can be equipped with atomizing spraying system to add liquid to the materials.

4.Fish Feed Extruding

After mixing, fish feed pellet extruder can be adopted at this stage to compress feed powder into sized pellets. We have dry type fish feed extruder and wet type fish feed extruder for pelletizing. Wet type feed extruder is equipped with conditioner and can produce high quality pellets in large capacity, so it is suitable for large fish feed factory. While dry type fish feed extruder suits for small aquatic farms.

5.Fish Feed Pellet Drying

Pellets are in high temperature and moisture content after extruding, so fish feed pellets dryer is needed to cool and dry pellets. Featured by simple structure and high efficiency, feed pellet dryer is ideal for drying.

6.Oil Spraying

Oil spraying process. The good taste and nice smell of the end product is owed to the Oil Spraying Machine. This equipment rotates with high speed, spraying atomized oil on both surfaces of the fish feed pellets. Excess oil during this process is then recycled through a special filter.

7.Pellets Cooling

Pellet cooling. When the temperature of the oil-sprayed pellets increases, they become soft, and can easily break. To avoid loss in this regard, the feed pellets must be cooled, and are consequently hardened. The cooling type adopted by most fish pellet plants is the counter flow cooler where the fish feed pellets are in opposite direction to the air cooling them.

8.Fish Feed Pellet Packing

To make pellets easy to store, transport and sell, they should be packed properly. Pellets weighing and packing can be finished at the same time. Moreover it can also prevent feed deterioration and thus prolong its shelf life. Pellets packing machine can largely reduce labor cost and increase working efficiency.

Reply comment