Large capacity fish feed pellet production line

fish feed pellet production line is the complete procedure of feed pellet production with capacity of 0.1-4 t/h, which is the best choice for small, medium and big sized feed mills and breeding farms. floating fish feed pellet production line is designed for making commercial pellets from corn, maize, grass, grains, protein, molasses and so on.

Product Description

Floating fish feed production line can process and extrude 1.5mm, 2.0mm-13mm feed. These feed is suitable for shrimp, crab, fish, sea cucumber, turtle, loach, eel and other freshwater aquatic animals. The single-screw wet feed extruder is used in the fish and shrimp feed pellet production line, as main extruding machine. This fish feed machine improves the quality of feed pellets, reduces the loss of water-soluble vitamins in water, has a lure effect and improves palatability.

Professional engineers design different production lines for fish and shrimp feed pellets according to the needs of customers. Fish feed machine, crusher or mixer can be exchanged and matched.

Main fish feed machine technical parameters

| Dry fish feed machine | |||||

| Name | Capacity (T/H) | Host Power (KW) | Feeding Power (KW) | Spiral Diameter (MM) | Cutting Power (KW) |

| DGP40-C | 0.03 - 0.04 | 5.5 | 0.4 | Φ40 | 0.4 |

| DGP50-C | 0.06 - 0.08 | 11 | 0.4 | Φ50 | 0.4 |

| DGP60-C | 0.1 - 0.15 | 15 | 0.4 | Φ60 | 0.4 |

| DGP70-B | 0.18 - 0.2 | 18.5 | 0.4 | Φ70 | 0.4 |

| DGP80-B | 0.2 - 0.3 | 22 | 0.4 | Φ80 | 0.6 |

| DGP90-B | 0.3 - 0.4 | 37 | 0.6 | Φ90 | 0.8 |

| DGP120-B | 0.5 - 0.6 | 55 | 1.1 | Φ120 | 2.2 |

| DGP135-B | 0.7 - 0.8 | 75 | 1.1 | Φ133 | 2.2 |

| DGP160-B | 1 - 1.2 | 90 | 1.5 | Φ155 | 3 |

| DGP200-B | 1.8 - 2 | 132 | 1.5 | Φ195 | 3.0 - 4.0 |

| Wet fish feed machine | ||||||

| Name | Capacity (T/H) | Host Power (KW) | Feeding Power (KW) | Spiral Diameter (MM) | Cutting Power (KW) | Tempering Power (KW) |

| DSP60-B | 0.18 - 0.2 | 15 | 0.4 | Φ60 | 0.4 | 0.75 |

| DSP70-B | 0.25 - 0.30 | 18.5 | 0.6 | Φ70 | 0.6 | 0.75 |

| DSP80-B | 0.35 - 0.40 | 22 | 1.1 | Φ80 | 0.8 | 1.1 - 1.5 |

| DSP90-B | 0.50 - 0.60 | 37 | 1.1 | Φ90 | 1.1 | 2.2 |

| DSP120-B | 0.70 - 0.80 | 55 | 1.1 | Φ120 | 1.5 | 2.2 |

| DSP135-B | 1.0 - 1.2 | 75 | 1.5 | Φ135 | 2.2 | 3.0 - 4.0 |

| DSP160-B | 1.8 - 2.0 | 90 | 2.2 | Φ155 | 2.2 - 3.0 | 4.0 - 5.5 |

| DSP200-B | 3.0 - 4.0 | 132 | 2.2 | Φ195 | 3.0 - 4.0 | 5.5 |

Features

The advantages of feed pellets produced by fish feed machine

(1) The feed produced by fish feed extruder retains a large number of beneficial live bacteria and a variety of active proteins, which can be directly consumed by shrimp, crab, fish, turtle, loach, yellow frog, etc. At the same time, it can also cultivate bait organisms, indirectly for shrimp, Crabs, fish, sea cucumbers, turtle loach, eel, etc. and provide nutrition without polluting the water quality.

(2) The feed produced by fish feed extruder can not only play a role in attracting and promoting the digestion and absorption of shrimp, crab, fish, sea cucumber, turtle, loach, eel, etc.

(3) The feed produced by fish feed extruder retains the growth of the flora, which can effectively prevent the occurrence of moss in the pond, greatly reduce the workload of shrimp, crab, fish, sea cucumber, soft-shelled turtle, loach, eel, etc., and reduce the cost of breeding medicines and diseases occur.

Why choose the fish feed production line?

1. The raw material is easy to find, just like corn meal 50%, wheat middling flour 40%, soybean meal 3%, rice flour 5%, meat 2%

2. The output pellet can floating on water within 12Hours not sink and not dispersing

3. Not sink and not dispersing keep water clearly no polluting.

4. After puffed feed pellet through high temperature will killing such as Escherichia coli and Salmonella, not only keep fish eat health food, also keep fish easy to eat and digest, make your fish growing fast.

5. Can make different size from 1mm-12mm , can feed from baby fish to big fish

6. Can using motor and diesel according to your requested

7. Easy to operate and learning .

8. We have semi-automatic and automatic from 50kg/h-8T/h output for your choice.

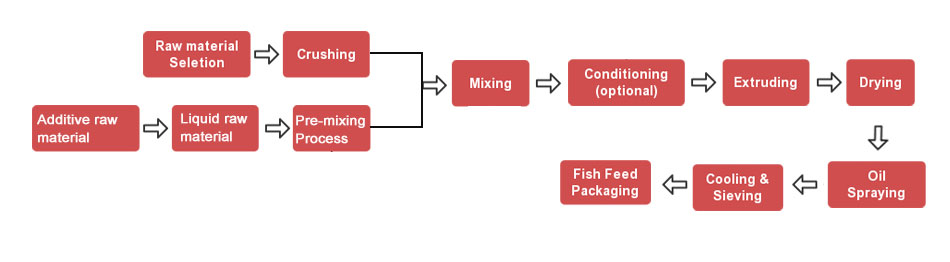

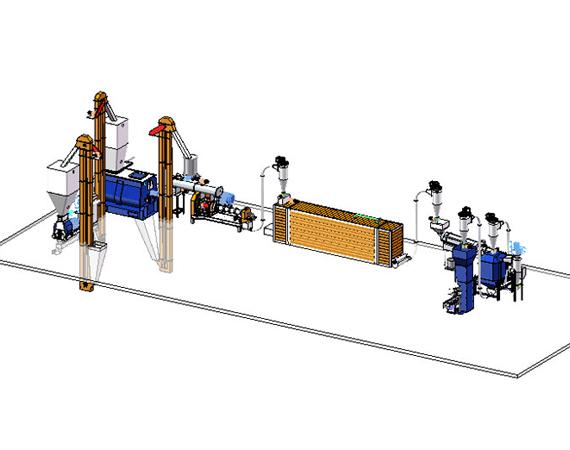

Flowchart of fish feed production line

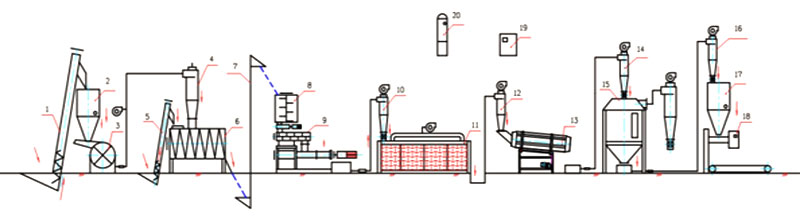

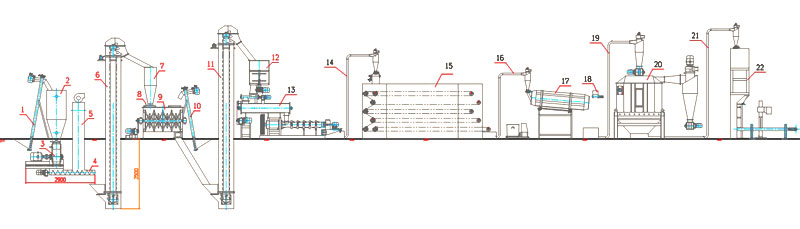

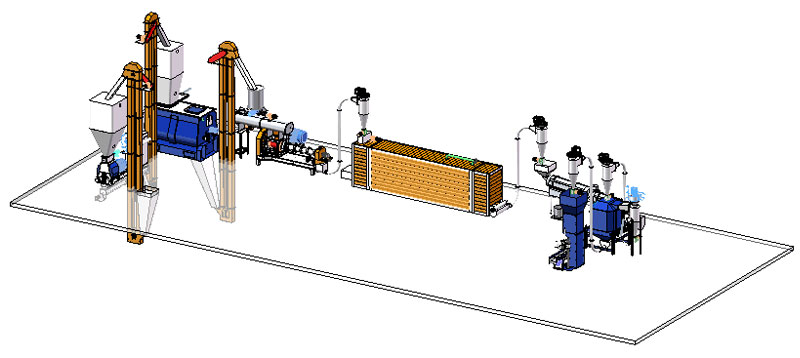

1. Process introduction:

Crushing raw materials → preparation of raw materials (corn flour, soybean meal, starch, fish meal, etc.) → mixing system → conveyor → single-screw feed extruder → conveying → drying machine (electric oven, gas fuel oil oven or steam oven) → oil injection → Single barrel seasoning system → cooling conveyor → screening → silo → packaging machine

2. The configuration of puffed fish feed processing equipment:

Crusher → Mixer → Conveyor→ Single-screw feed extruder → Conveyor → multi-layer dryer → season machine → cooler → vibration screen → packaging machine.

Steps of making floating fish feed pellet

1.crushing raw material: feed crusher machine

Raw material ingredients should be grinded to the required size by feed grinder. hammer mill also called Wide chamber Fine feed Hammer Mill, is mainly applied to fine grinding of meals for special aqua feed.

2. mixing raw material: feed mixer machine

Mixing the material thoroughly can ensure extruding efficiency and improve the feed quality.the feed mixer can be customized with atomizing spraying system which will add liquid like molasses and grease to material more evenly.

3.extruding raw material: floating feed pellet making machine

our floating fish feed pellet making machine can be divided into two types: dry type fish feed processing machine and wet type fish feed processing machine. The wet type is with the conditioner and need to equip the steam boiler. The dry type fish feed production line is cheaper while the capacity of the wet type fish feed making machine is higher, so usually the wet type fish feed extruder is suitable for large feed pellet factory and the dry type fish feed processing machine is better and economic for the small and medium size user or factory.

4. drying final pellets: feed pellet dryer

our mesh belt dryer is a continuous convective belt dryer.Pellets formed through the extruder are stacked in layers on a wire mesh or perforated plate belt conveyor and conveyed continuously through drying chambers. During this process,the drying air is passed repeatedly through the products layer until pellets have the optimum moisture content before leaving the dryer.While if you choose wet type fish feed machine, we recommend the gas type pellet dryer.

5.cooling final pellets: feed pellet cooler

Pellet cooling When the temperature of the oil-sprayed pellets increases, they become soft, and can easily break. To avoid loss in this regard, the feed pellets must be cooled, and are consequently hardened. The cooling type adopted by most fish pellet plants is the counter flow cooler where the fish feed pellets are in opposite direction to the air cooling them.

6. packing final pellets: automatic packing machine

To make the finished pellets easy to store, transport and catch the clients' eyes, they should be packed properly. With our electronic weighing and packing machine, the finished pellets can be packed into bags, weighed, conveyed, and sealed automatically, which saves labor and time greatly and meet the requirements of large scale production.For this packing machine, automatic heat typing code, automatic bag sewing and automatic thread cutting can be optional functions.

Solutions of wet type fish feed pellet line

200kg-800kg floating fish feed pellet production line

1t-4t fish feed pellet line

3t fish food production line

Reply comment